Brief Introduction of the Application of High-power Three-phase Off-grid Inverter in Photovoltaic System

In the off-grid solar system, the most important device is the off-grid inverter. Generally, off-grid inverters include two types that one is integrated design, as the name suggests, the integrated off-grid inverter integrates the MPPT controller and the inverter. This kind of inverter has a simple structure and easy to install and transport. For projects with small load power, users would like adopt this type. However, if the power demand exceeds 80kW, the split-type off-grid inverters, MPPT controller is independent from inverter, is more welcomed in mainstream market.

For big capacity off-grid solar project, if choosing all-in-one off-grid inverter, there’re some disadvantage as follow. Firstly, it has large size. Also, the installation and transportation will be inconvenient. Secondly, the heat dissipation may be a problem. Combine the above considerations, in the application of high power off-grid project, split-type off-grid inverter will be proper solution since this two parts, MPPT controller and Inverter, are independent in structure.

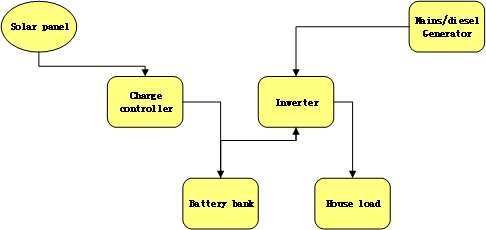

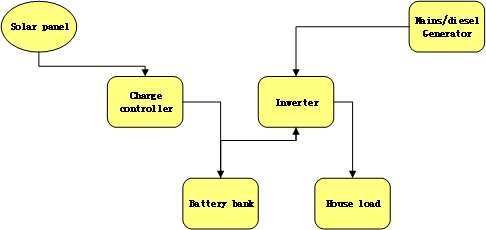

Split-type off-grid inverter block diagram

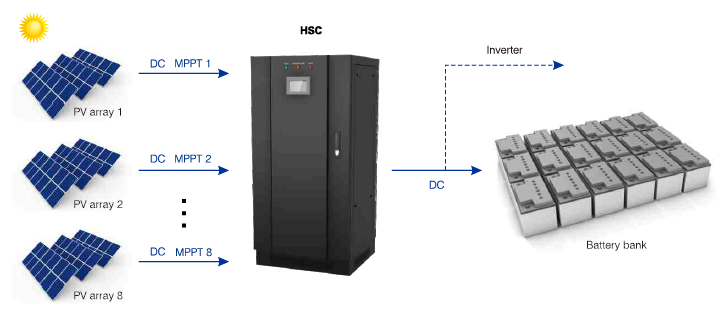

This article takes JFY HSC series MPPT controller and IPS series inverter as an example to introduce the application of split-type off-grid inverter. The HSC series is solar controller, and the power range is from 10 kW to 160 kW. It uses MPPT control algorithm, ensuing has a high efficiency. And also it adopts modular design (10KW/15KW/20KW three kinds of modules), each module is an independent MPPT. Meanwhile, It has complete functions and protection mechanisms such as intelligent battery management, temperature compensation and RS485/dry contact communication etc.

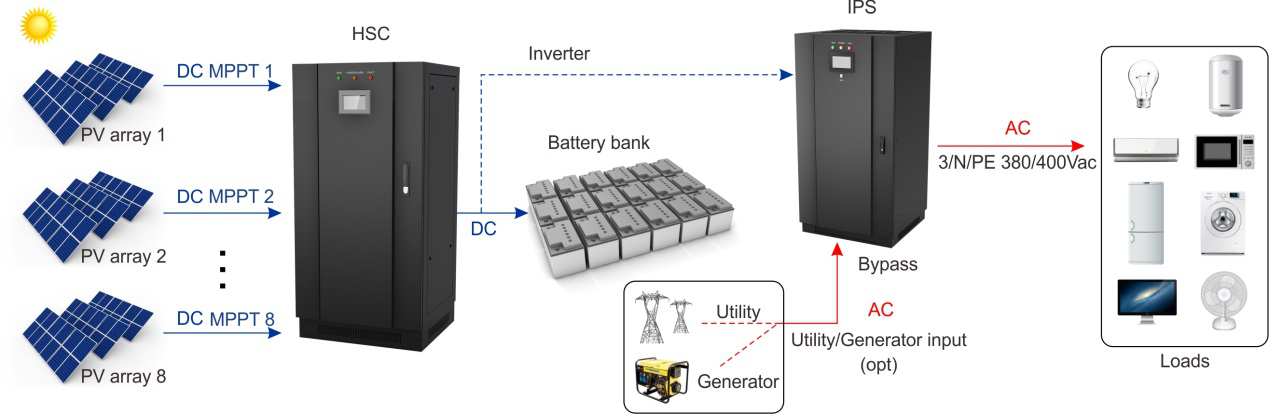

JFY HSC Application System Diagram

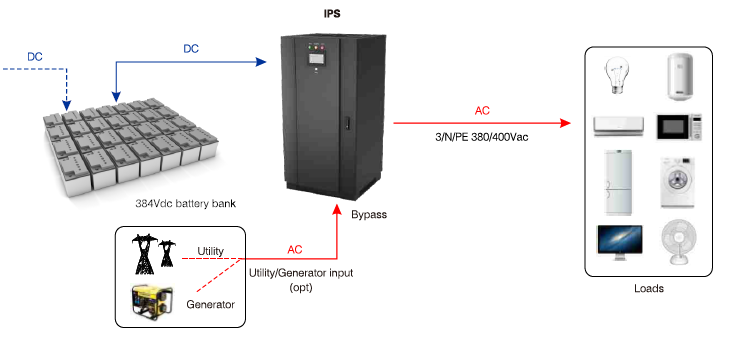

IPS series inverters always work with HSC series MPPT controller together, power range of 80KW~160KW, built-in isolation transformer, support three-phase 100% unbalanced load, pure sine wave output, efficiency up to 95%. It has utility and diesel bypass functions and RS485 communication interface.

IPS Series Inverter System Diagram

Since the MPPT controller and the inverter are separate, which makes the system configuration more flexible. In conventional off-grid system design, two important factors are generally taken into account when selecting an inverter and controller, which is “peak load power" and "load daily power consumption". The peak power determines the power of the off-grid inverter. The daily power consumption determines the capacity of the PV module, which also determines the capacity of the MPPT controller. If adopt the integrated off-grid inverter solution, due to the MPPT control circuit and the inverter circuit all-in-one design, the manufactures always keep those two parameters in same . For example, JFY XPI 5KVA all-in-one off-grid inverter, the input power of 5760W and output power of 5000VA, the MPPT control part and the off-grid inverter part are almost both 5kW. Although this kind of inverter structure very simple. However, in some special applications, due to the parameters of PV module capacity and load power are different, so choosing the integrated inverter will also face the problem of waste power. This difference may not be obvious in low power off-grid systems. But in high power off-grid project, the difference will be significant.

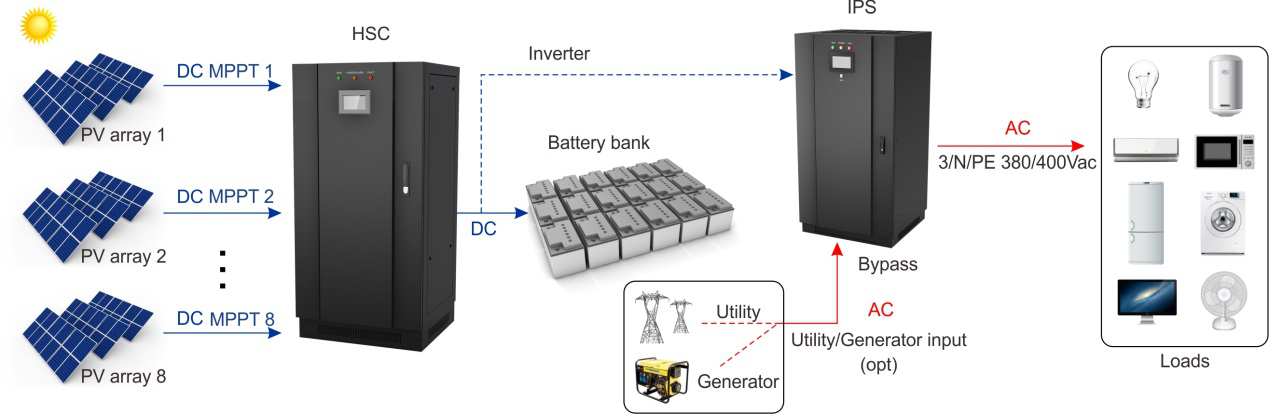

HSC Series MPPT Controller + IPS Series Off-grid Inverter System Diagram

Such as in following two situations:

First, the peak load power is large but its running time is short, and the daily power consumption is small. In order to meet the high peak power output, it is necessary to select a higher power inverter to match the load, i.e.: PV module power < load peak power.

For example, in some areas, the average duration of sunshine is 5 hours/day, the load is important industrial device with peak power of 160KW and the peak working hour of 2 hours per day, and the daily electricity consumption is about 320KWH.

Without considering of the utility or generator as backup conditions. According to above conditions, the inverter capacity should be 160KW at least. The capacity of PV module needs to meet the daily power consumption requirement. Assuming the overall efficiency of the system is 80%, the minimum PV module capacity is about Wp=320KWH/(5H*80%)=80KW. At this time, the MPPT controller corresponds power is about 80KW.

Secondly, the load power is low but the continuous working time is long, and the daily power consumption is large. In order to meet the demand, it is necessary to configure the much higher capacity of PV module. At this time, it is necessary to select a larger power MPPT controller. i.e.: PV module power > peak load power.

For example, in some areas, the average duration of sunshine is 5 hours/day, the load is electrical devices in office workplaces with peak power of 80KW. And, normal working hours is 8 hours, the daily electricity is about 640KWH.

Without considering of the utility and generator as backup conditions. According to the load power, the inverter capacity should be 80KW at least. The capacity of the PV module should meet the daily power consumption requirement. Assuming the overall efficiency of the system is 80%, the minimum PV module capacity is about Wp=640KWH/(5H*80%)=160KW. Meanwhile, the MPPT controller capacity should be 160KW approximately.

Based on the above cases, in a high-power off-grid solar system, the power selection of the inverter and the controller may not be the same. JFY HSC series MPPT controller adopts modular design, which is more convenient for system expansion. Together working with IPS series inverter, system can maximize device performance while keeping costs to a minimum.

JFY 840kW off-grid solar project at Xinjiang, China

JFY has a very complete photovoltaic off-grid inverter product line of power range 0.5-160kW, covering single-phase and three-phase applications. In addition to the IPS series split-type off-grid inverter, JFY also has the integrated off-grid inverters, such as ESS-B series 10~20kW and ETS-B series 10~60kW inverters.